仓库自动化不仅仅是为了降低人工成本,它还关乎实现更高的吞吐量、始终如一的精度和长期的运行可靠性。诸如用于托盘货物存储和处理的堆垛机、用于自动化的仓库垂直升降机以及自动化托盘传输系统等自动化系统如今已被视为现代配送中心必不可少的基础设施。然而,与任何机械系统一样,这些解决方案的使用寿命在很大程度上取决于设计、使用和维护。

自动化设备的使用寿命很少是一个固定的数字。相反,它受几个变量的影响:

| 因素 | 对寿命的典型影响 | 笔记 |

| 负载能力利用率 | 高负荷缩短寿命 | 容量超过 80% 时,电机寿命将缩短约 25% |

| 操作环境 | 灰尘、湿度或温度波动会加速磨损 | 理想温度:18–25°C,低尘 |

| 维护频率 | 预防性维护可将使用寿命延长 40% | 缺乏润滑是导致故障的主要原因 |

| 系统设计和质量 | 更高级的组件使用寿命更长 | ISO 认证的设计通常运行时间延长 20% |

| 操作员培训 | 使用不当会减少服务时间 | 错误导致的停机缩短了变速箱的寿命 |

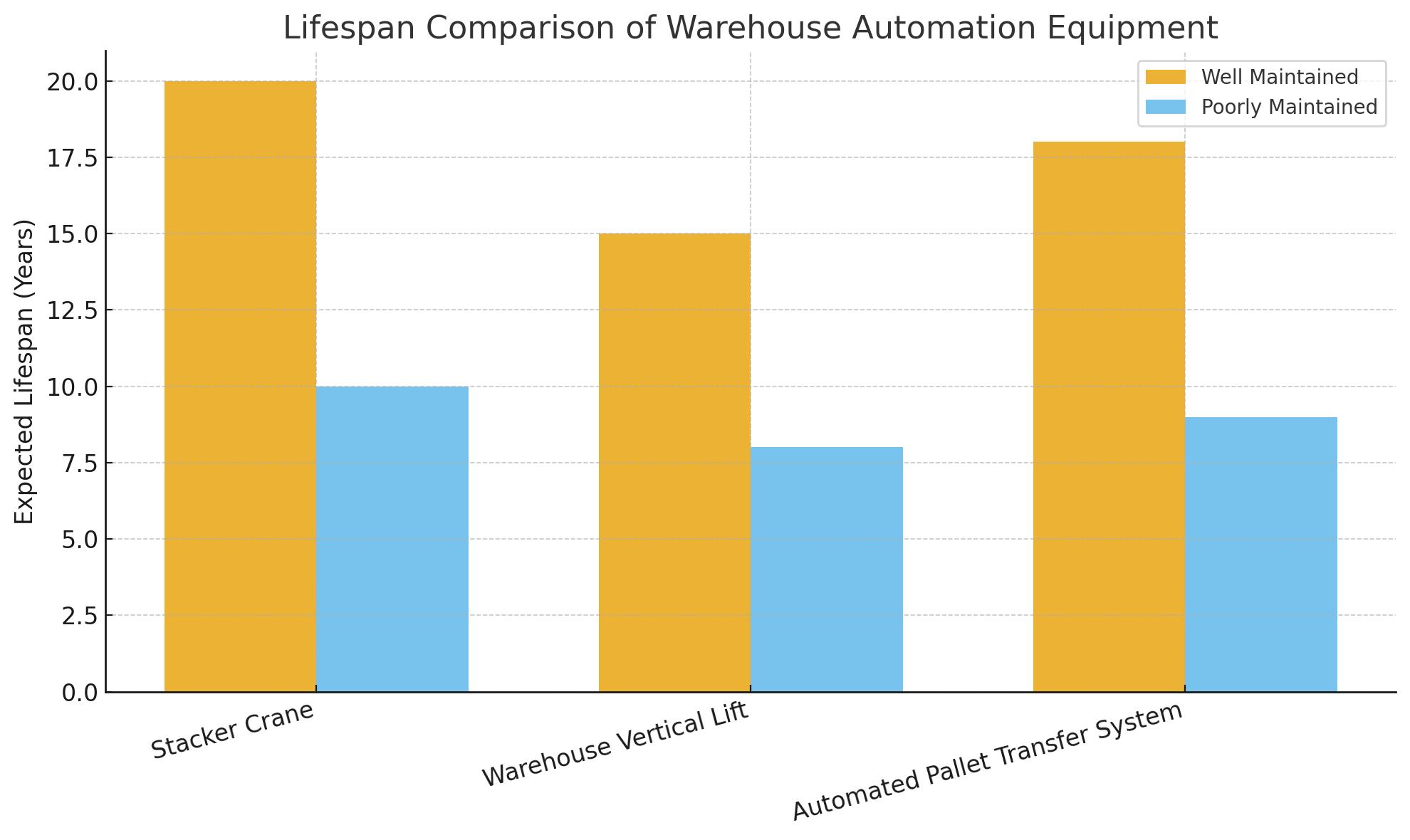

例如,欧洲物料搬运联合会的数据显示 用于托盘装载存储和处理的堆垛起重机 在清洁和维护良好的环境中,可以高效运行 15 至 20 年,而被忽视的系统可能需要在 8 至 10 年内进行大规模更换。

上图比较了三个核心仓库自动化系统的预期运行寿命——用于托盘装载存储和处理的堆垛机、用于自动化的仓库垂直升降机和 自动托盘传输系统 —在不同的维护条件下。

这些数据强调了为什么日常维修、状态监测和及时更换零件不仅是最佳实践,而且是仓库效率的关键投资。

自动化系统很少会在没有信号的情况下发生故障。识别早期迹象对于避免意外停机至关重要。

仓库垂直升降系统开始消耗比平均水平多 10-15% 的电力,这可能是因为电机磨损或轨道未对准。

如果自动托盘传输系统每 500 个周期就会出现一次托盘错位,而不是每 5,000 个周期出现 1 次,那么这是一个危险信号。

堆垛起重机中的轴承和变速箱在发生重大故障之前经常会发出明显的振动。

当单元负载堆垛起重机的检索周期开始需要 12 秒而不是设计的 8-9 秒时,性能下降是显而易见的。

行业基准表明,自动化仓库每月停机时间超过 4% 即被视为过长。

延长仓库自动化的运行寿命需要结合技术升级和规范的维护。

按照制造商建议的时间间隔润滑关键部件。

使用振动传感器和热像仪来预测故障的发生。

避免起重机或升降机持续以最大额定负载运行。以最大负载的70%到80%运行可延长系统寿命近30%。

灰尘过滤器、温度调节和湿度控制可防止敏感电子设备和电机过早磨损。

使用现代 PLC(可编程逻辑控制器)或伺服驱动器改造旧系统可以提高精度并减少机械部件的压力。

根据高架仓库的实地研究,训练有素的操作员可以将碰撞相关事故减少 40% 以上。

仓库自动化是一项长期投资。选择像堆垛机这样的设备来存储和处理托盘货物,或者 仓库自动化垂直升降机 不考虑生命周期成本可能会导致过早更换。整体方法包括:

评估总拥有成本 (TCO) 而不是前期成本。

从一开始就规划维护预算。

为使用寿命较短的部件(例如传感器、滚轮)创建更换路线图。

如果实施得当,自动化托盘传输系统可以可靠运行 15 年以上,前提是它有预测分析和定期检查的支持。

| 设备类型 | 预期寿命(保养良好) | 寿命缩短(维护不善) |

| 托盘堆垛机 | 18–20岁 | 8-10岁 |

| 仓库自动化垂直升降机 | 12–15岁 | 6–8岁 |

| 自动托盘传输系统 | 15至18岁 | 7–9岁 |

对于追求规模扩张的企业来说,仓库自动化已不再是可有可无的选择。但仅靠自动化并不能保证效率。系统的使用寿命与其管理方式息息相关——从负载控制到预测性维护。通过观察早期预警信号并投资定期维护,企业可以最大限度地提高自动化投资回报,并确保系统数十年内始终保持可靠的性能。